The thermal conductivity detector (TCD) was the first gas analyzer used in 1920 in the chemical industry for process measurements in order to determine the quantitative composition of gas mixtures.

Each gas has its typical thermal conductivity depending on its viscosity, molar weight, and temperature. The influence of gas pressure on thermal conductivity is insignificant.

Measuring is based on the principle, that when mixing gases with different thermal conductivities their mixture has a thermal conductivity dependent on the concentration of its constituents. Thereby portions of individual gases can be determined.

All Messkonzept GmbH instruments (FTC400, FTC300, FTC200-OEM, and FTC130) register quantitative compositions of gas mixtures by measuring the thermal conductivity of gas mixture between a heat source and a heat sink.

The measuring gas is directed through a stainless steel block, which is heated up to 63 °C. A control system keeps this temperature constant; the block serves as a heat sink.

A micromechanically fabricated membrane with an applied thin-film resistor serves as a heat source. Its temperature is maintained constant at 135 °C by a second control system.

Below and over the membrane small cavities are formed into which the measuring gas can diffuse. The sides of the cavities opposite to the membrane are thermally connected with the heat sink.

Depending on the thermal conductivity of the measuring gas the heat source loses more or less energy which is compensated through heating. The voltage necessary for maintaining the constant temperature of the membrane is a measurement for the thermal conductivity of the measuring gas.

In contrast to the older measuring devices functioning based on the thermal conductivity principle the Messkonzept GmbH instruments make do without any reference gas. This reduces consumables, response time, and allows a very compact overall dimension.

The principle of measurement of thermal conductivity is especially well applicable when the gases which need to be measured differ distinctly with regard to their thermal conductivity and when one of the three following criteria is fulfilled:

Thermal conductivity of all gases increases with temperature. The increase of thermal conductivity is very different for various gases. On the customer’s request it can be checked, if it is possible to increase measuring sensitivity or decrease cross sensitivity by changing the temperature of a heat source and / or of a heat sink.

Cross sensitivity means measurement sensitivity to a gas different from the measuring component. On the contrary, interference susceptibility designates sensitivity to everything that does not concern gas composition, for example, to the pressure of measuring gas.

Processes with corrosive constituents are the applicative challenge in gas analytics. Some gases form compounds with moisture which corrode components in contact with the measuring gas, hereby impair measuring accuracy, ultimately destroy, the measuring capability.

Therefore, at Messkonzept GmbH we only use the highest-quality materials for gas paths, such as stainless steel 1.4571 and O-Rings made of FPM (Viton®) or FFKM (Kalrez®), highly resistant fluoro-elastomers.

However, the micromechanical sensor unit offers a vulnerable contact surface for gases with high corrosion potential. Messkonzept GmbH has developed an effective protective coating specially for this area. If risk of corrosion exists, a sensor unit is built in, which is coated with a 4µ-thick halogenated polymer layer. The excellent measuring properties of the sensing units are not affected by this coating.

Frequently, the gases which are to be determined are laden with moisture. If the humidity is not an important measuring component and the moisture content is relatively constant, its content can be calibrated. Thus, an error-free determination of the relevant measurement component in a quasi-binary mixture with moisture as a component is often possible. However, if one is also interested in the measurement of humidity or if the moisture content fluctuates, we at Messkonzept GmbH offer a selective determination of the humidity with a capacitive humidity sensor in the range 0-10 vol.%.

On the one hand, this integrated solution makes it possible to compensate for the error which a fluctuating moisture content exerts on the determination of the measured variable (see cross-sensitivity compensation) and, on the other hand, to provide a measured value for the moisture.

The sensor unit is protected by a sinter frit with pore sizes in µm range which is impenetrable for liquids but can be overcome by molecules of measuring gas almost without resistance. The sinter frit also reduces the already insignificant dependence of the measuring signal on gas flow so the measuring gas can be streamed through the TCD with the wide range from 10 L/h to 400 L/h.

Molecules like CO2, CH4, C2H6, CO, NO, SO2 and H2O absorb infrared radiation. The range of absorption in the wavelength spectrum is a “fingerprint” for the identification of the sort of molecules. The level of absorption is a measure of the concentration of the gas concerned. The selective measurement of up to three infrared-active gases in one mixture is enabled by a detector, which tests the absorption with three interference filters at three different wavelengths. The selection of the interference filters thus determines which gases are analyzed. A fourth measurement channel is in a wavelength range where no absorption of any of the gases occur. Thus the intensity of the IR radiator is determined and serves as a reference. The combination of the IR measurement with the thermal conductivity measurement enables the complete determination of complex gas mixtures in many cases.

Flow measurement, independent of gas type, for binary mixtures in the range 0 to 130 l/h A very sensitive measurement of the pressure drop over a laminar flow-restrictor provides a measurement of the gas flow. This pressure drop, however, also depends on the type of gas.

Since the composition of the gas is known from the thermal conductivity measurement, the gas dependence of the flow measurement is compensated by calculation. In this way, a flow-through measurement is provided which no longer depends on the type of gas.

| FTC300:Flow measurement | FTC300:Flow monitor | |

|---|---|---|

| Measuring range (MB) | FTC300:Flow measurement0-130 l/h | FTC300:Flow monitor0-130 l/h |

| Noise | FTC300:Flow measurement<2% of range | FTC300:Flow monitor<2% of range |

| Drift weekly | FTC300:Flow measurement<1% of range | FTC300:Flow monitor<1% of range |

| Repeatability | FTC300:Flow measurement<1% of range | FTC300:Flow monitor<1% of range |

| Non-linearity | FTC300:Flow measurement<3,5% of range | FTC300:Flow monitor<10% of range |

| Measuring error in case of change-temperature modification per 10°K | FTC300:Flow measurement<0,1% of range | FTC300:Flow monitor<0,1% of range |

| Fault with pressure change measurement gas per 10 hPa | FTC300:Flow measurement<0,1% of range | FTC300:Flow monitor<0,1% of range |

| T90-time | FTC300:Flow measurement5 sec | FTC300:Flow monitor5 sec |

| Approved pressure range | FTC300:Flow measurement800 hPa to 2000 hPa absolute | FTC300:Flow monitor800 hPa to 2000 hPa absolute |

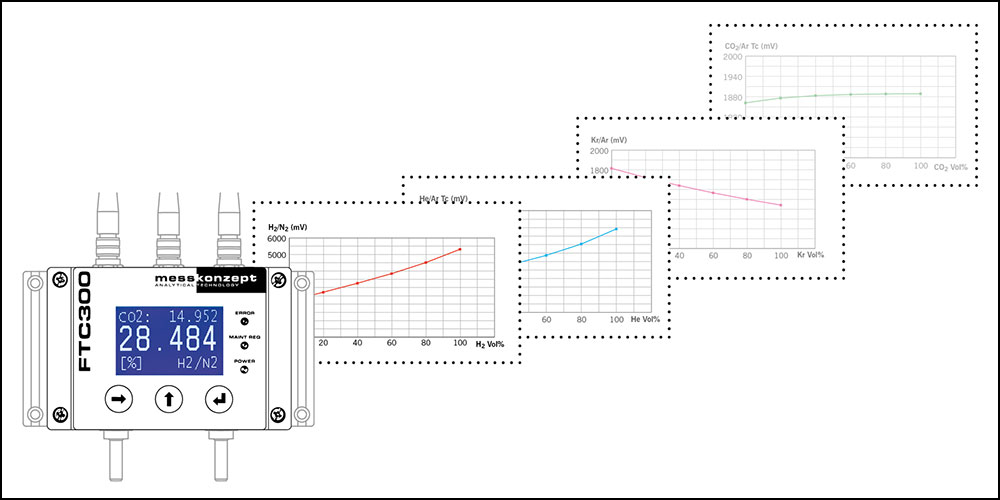

Often it is desirable to cover different measuring tasks such as the measurement of different gases and gas mixtures with one measuring device. For this type of application, the so-called multi-gas mode (MGM) has been developed.

The linearizations and calibration data for up to 16 gas pairings are stored in one device.

By simply switching on the control panel or by remote control, the respective gas pair can be activated and the measurement can be carried out. In the table on the FTC300 page, up to 16 binary gas mixtures are marked with MGM, which are standardized in the FTC devices. Custom extensions are of course possible.

Pure gases and gas mixtures of defined quality are required for a large number of applications. Both in bottling and in the feeding and mixing of gases, an independent proof of quality is often desirable and sometimes indispensable. The same measuring task often occurs in the receipt of goods when gases in bottles or pipelines arrive for further use. With the MGM function, these measurement tasks can be performed with one device.

Mulit Gas Mode also simplifies warehousing and shortens replacement purchases for many of our customers. At the touch of a button, a universally equipped measuring device is adapted for a specific measuring task.

The system manufacturer and system operator are liable for safe handling combustible gases and use of appropriate installations. In particular, it is necessary to test the measuring gas path for leak proofness prior to commissioning the analyser system. If combustible gases are to be directed into the analyser of Messkonzept GmbH, we urgently recommend choosing the option “Filling with glass beads”. These glass beads with a diameter of 0.6 mm are compacted by vibration, that all cavities in the analyser case are densely filled. In the improbable case of leakage in the internal gas path of the analyser system the free volume in the casing is reduced significantly.

Modeling of the cross sensitivity and additional measurements allow the complete determination of complex gas mixtures The thermal conductivity measuring method, combined with other gas-analysis methods, provides the input signals for a computational compensation process which was modeled beforehand in an experiment.

Up to now, systems with several analyzers were necessary to determine the various input signals. By means of the integrated IR and humidity measurement, as well as the internal computing capacity, an integrated solution for the determination of homonuclear and noble gases in complex gas mixtures is achieved.

Naturally, the IR signal changes proportionally to the absolute pressure. The TCD signal also shows a strongly increasing pressure dependence under absolute 800hPa. In order to compensate for this interference, a measurement of the absolute pressure can be integrated. By means of the previously experimentally determined modeling of the influence of pressure the interference is calculatively eliminated.

By submitting the data entered in the contact form by clicking on the button below, you declare that you have read the privacy policy and that you agree that the data provided will be collected and stored electronically. The data is used only strictly earmarked for processing and answering your request. By submitting the contact form you agree to the processing. You may revoke your consent at any time with future effect. In case of cancellation your data will be deleted immediately.