Combination of different measuring methods:

In 2004, a way was found to measure flammable gas which avoided the customer having to laboriously purge the device housing. Instead, to measure flammable gases, the Messkonzept housings were tightly filled with glass beads so that no free volume was left in devices.

In 2005 we moved into new premises, which allowed us to build a well-equipped application laboratory, among other things. Finding solutions for complex measurement tasks for our customers could now be carried out in our lab.

To improve corrosion protection, in 2005 a conform coating of critical components with a 4µ halogenated polymer layer was developed. This technique has proved itself a hundred times over.

In 2006, the application area of measuring devices was again expanded by the introduction of hydrophobic filter membranes, which protect the sensor element against the destructive effects of condensation and repel dust. The gas flow is also not obstructed and the extremely fast measurement device response time was not substantially changed.

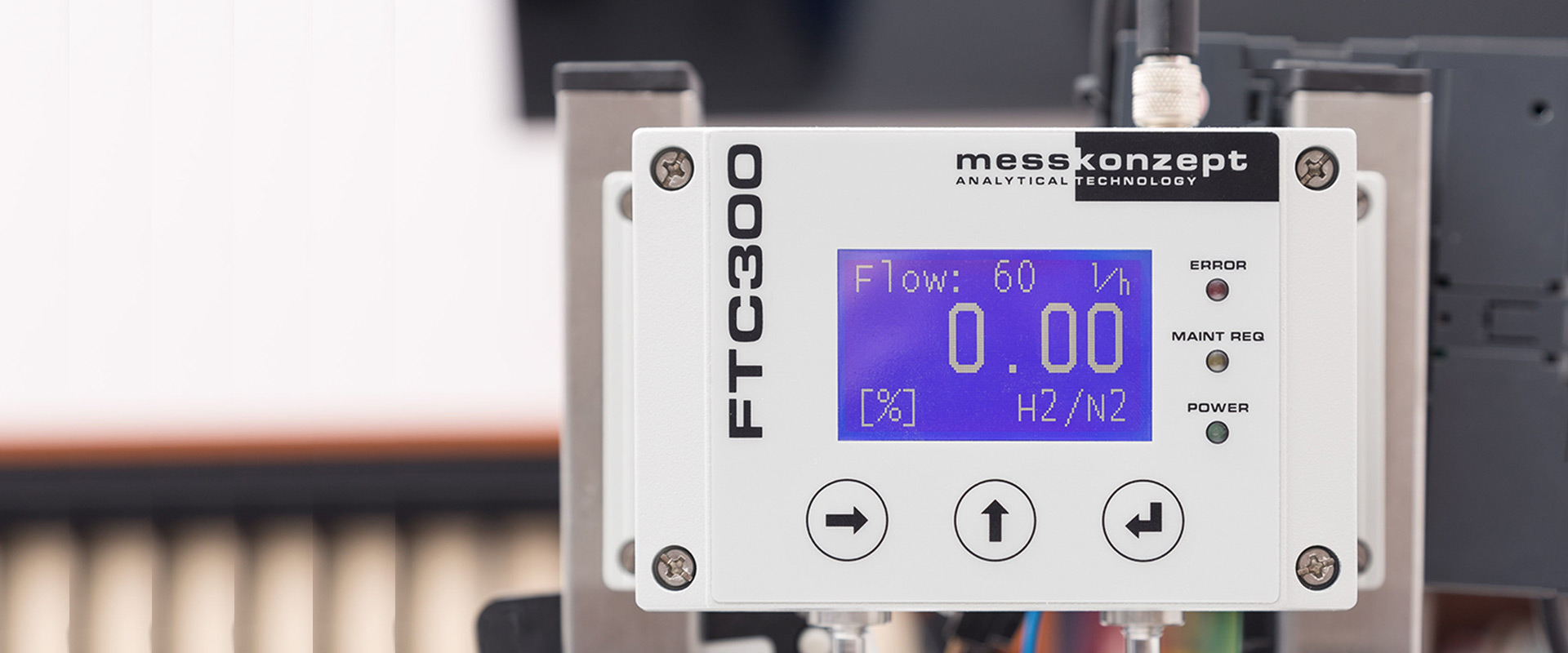

In 2009, the complete newly developed FTC200 analyzer was presented at the ACHEMA trade fair in Frankfurt. It combines outstanding measuring characteristics with compact construction and user-friendly menu navigation.

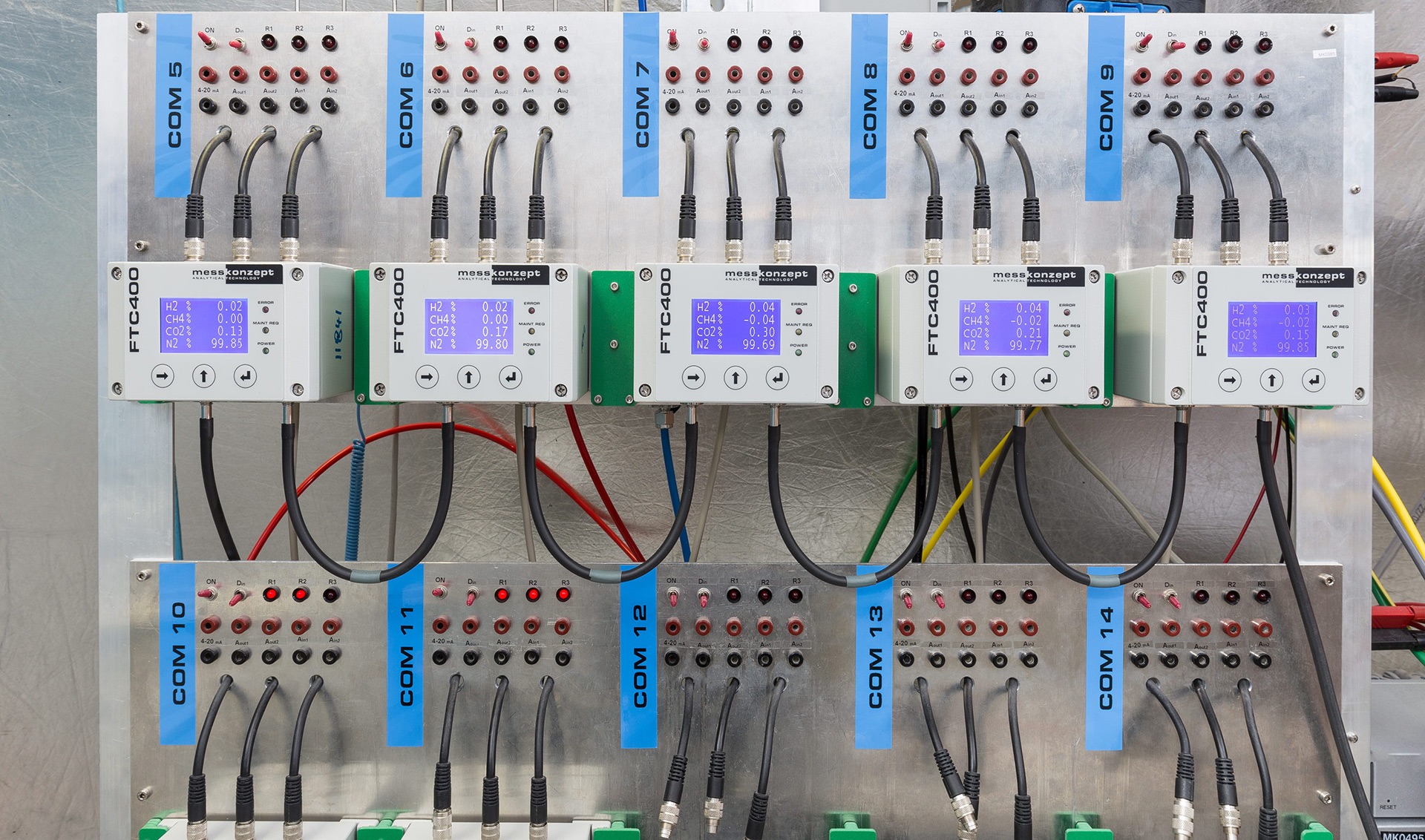

From 2010 until today, one major focus of our work has been on the creation of an intelligent process to compensate for cross-sensitivities. Together with the feeding of signals for the concentrations of cross-sensitive components, the effective processes enable the exact measurement of homonuclear gases such as H2, N2 and noble gases in non-binary gas mixtures.

The FTC400 was presented at the ACHEMA trade fair 2018. The compact instrument combines infrared photometry for up to 3 measurement gases with proven thermal conductivity technology. Thereby it enables the precise measurement of homonuclear gases such as H2, N2, and noble gases such as He, Ar, in complex non-binary gas mixtures and selective measurement of the infrared active gases like CO2, CH4, SF6, SO2, H2O and hydrocarbons without additional analyzers.

Alongside this device, a new FTC130 transmitter for extractive gas analysis and the non-extractive FTC160 were introduced, which both use thermal conductivity methods. They do not have a display, deliver 4-20mA signals, and can be calibrated and configured via the free use software SepApp 2.0.

Since August 2018, Messkonzept GmbH is certified according to ISO standard 9001:2015 by TÜV Hessen (German certification body).

The devices are characterized by a high measuring accuracy, stability and low influence by external influences.

Our customers value the accuracy and reliability of our gas meters.

A comfortable operating menu makes it possible to configure the device without much effort and to carry out an adjustment.

For devices without display, the comfortable operating program SetApp 2.0 is available for download.

Individual solutions are our strength. Every single measurement task contains process-related challenges, which we gladly accept.

Our solutions offer the possibility to optimize the measurement process and to integrate a stable and reliable solution in the long term.

By submitting the data entered in the contact form by clicking on the button below, you declare that you have read the privacy policy and that you agree that the data provided will be collected and stored electronically. The data is used only strictly earmarked for processing and answering your request. By submitting the contact form you agree to the processing. You may revoke your consent at any time with future effect. In case of cancellation your data will be deleted immediately.