Messkonzept GmbH gas measuring instruments are suitable for monitoring the purity of the individual gases during the incoming control, monitoring the mixing ratio and using the right gas or gas mixture in production.

Up to 16 gases and gas combinations can be tested with one device.

Suitable for the following Processes:

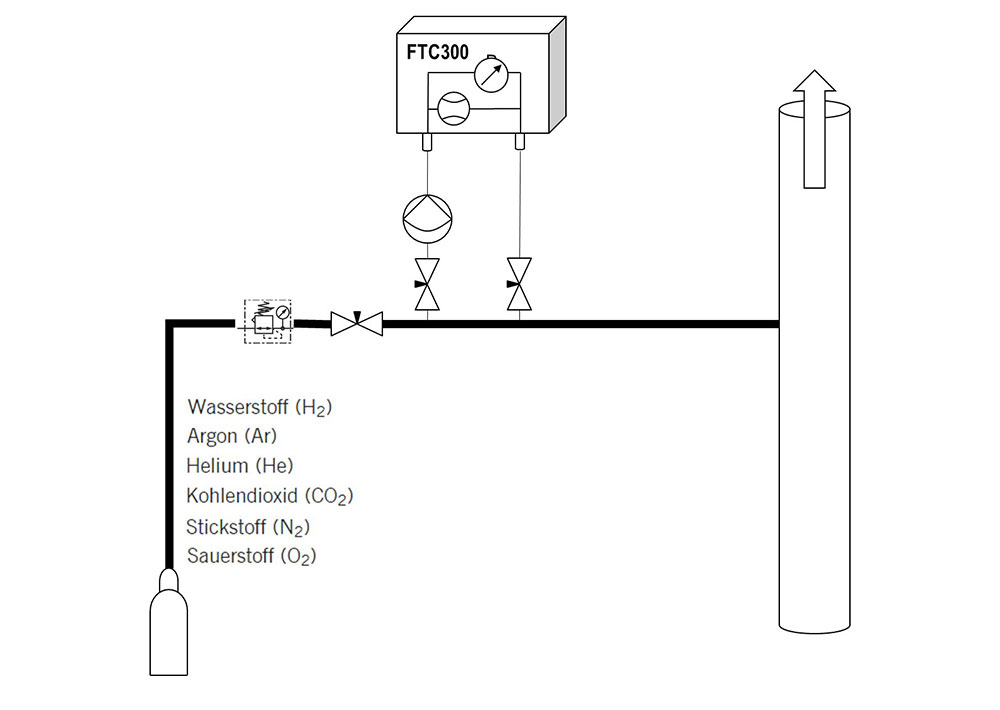

The delivered gases are checked for their purity. The meter is manually or automatically adjusted to the appropriate gas and T90 time below 1 second will quickly signal whether the process gas has the appropriate purity.

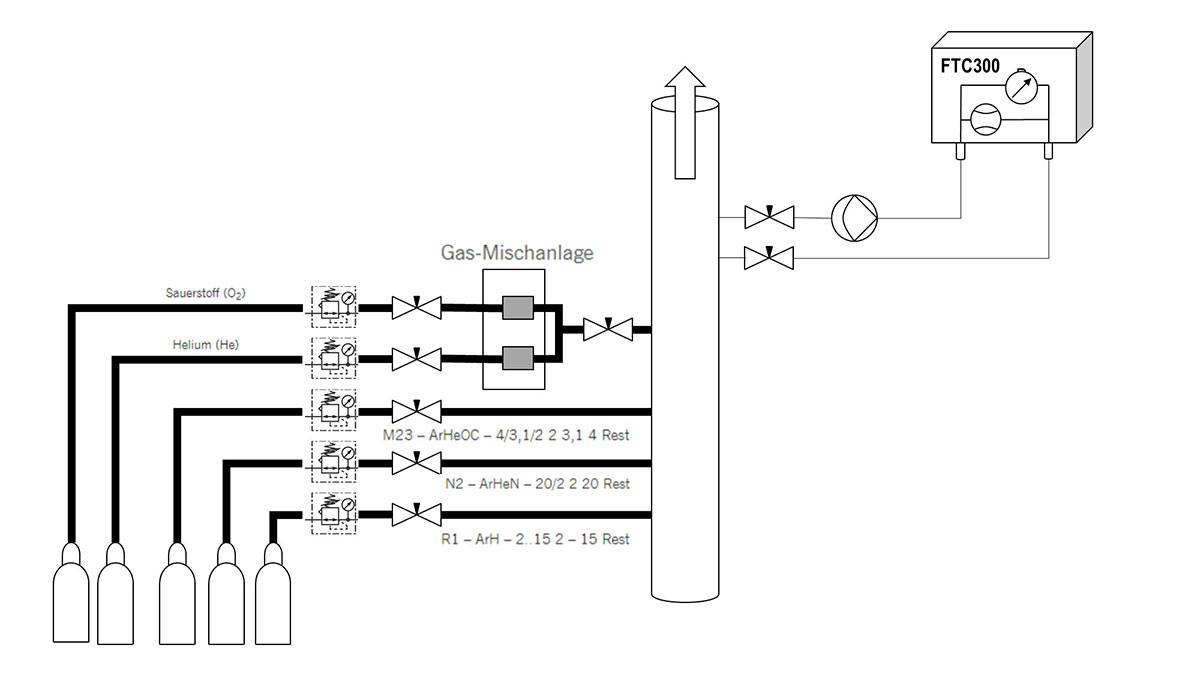

If a process gas is mixed together in an automatic process and used directly in the production line, the mixing ratios must be continuously checked to prevent usage of wrong amounts of welding gas. The low T-90 time as well as the sequential measurement of the process gas mixtures can indicate impurities or incorrect mixing ratios very quickly. The devices can be manually adjusted to the various measuring tasks on site only at the push of a button.

Some process gases or the process gas mixtures, e.g. Main group I, include gases that can be measured with the thermal conductivity. Other process gas main groups such as M1, M2, M3 contain CO2 which is infrared active and can only be measured with IR. FTC400 is ideal for this measurement task.

The DIN standard 14175: 2008 regulates the designations for process gases and mixed process gases used for joint welding and related processes.

The gases are divided into groups. The groups describe their chemical behavior and form main and subgroups.

The main groups indicate the chemical behavior:

| I: | inert process gases and process mixing gases |

| M1,M2m,M3: | Oxidizing process gases and process mixing gases containing oxygen or / and carbon dioxide. |

| C: | Highly oxidizing process gases and process mixing gases |

| R: | Reducing process gases and process mixing gases |

| N: | Reaction-bearing process gases and process mixing gases containing nitrogen |

| O: | Oxygen |

| Z: | Process mixing gases with components whose composition is outside the listed range. |

The subgroups indicate the different composition of the process gases within the main group.

Designation: mixed gas with 7% carbon dioxide, 4% oxygen and balance argon:

| Process gas name | Multiple selection |

|

|---|---|---|

| C1 | Kohlendioxid (CO2) CO2 100 Vol% |

|

| I1 | Argon (Ar) Ar: 100 Vol% |

|

| I2 | Helium (He) He: 100 Vol% |

|

| I3 | ArHe – 15 Rest He: 15 Vol%; Ar: Rest |

|

| I3 | ArHe – 30 Rest He: 30 Vol%; Ar: Rest |

|

| I3 | ArHe – 50 Rest He: 50 Vol%; Ar: Rest |

|

| I3 | HeAr – 10 Rest Ar: 50 Vol%; He: Rest |

|

| I3 | HeAr – 30 Rest Ar: 50 Vol%; He: Rest |

|

| M12 | ArC – 2,5 Rest CO2: 2,5 Vol%; Ar: Rest |

|

| M12 | ArHeC – 20/2 Rest He: 20 Vol% ; CO2: 2 Vol%; Ar: Rest |

|

| M12 | ArHeC – 50/2 Rest He: 30 Vol% ; CO2: 2 Vol%; Ar: Rest |

|

| M13 | ArO – 1 Rest O2: 1 Vol%; Ar: Rest |

|

| M13 | ArO – 3 Rest O2: 3 Vol%; Ar: Rest |

|

| M20 | ArC – 10 Rest CO2: 10 Vol%; Ar: Rest |

|

| M20 | ArC – 15 Rest CO2: 15 Vol%; Ar: Rest |

|

| M20 | ArHeC – 30/10 Rest He: 30 Vol% ; CO2: 10 Vol%; Ar: Rest |

|

| M20 | ArHeC – 35/15 Rest He: 35 Vol%; CO2: 15 Vol%; Ar: Rest |

|

| M21 | ArC – 18 Rest CO2: 18 Vol%; Ar: Rest |

|

| M21 | ArC – 25 Rest CO2: 25 Vol%; Ar: Rest |

|

| M22 | ArHeO – 25/3 Rest He: 25 Vol% ; O2: 3 Vol%; Ar: Rest |

|

| M22 | ArO – 8 Rest O2: 8 Vol%; Ar: Rest |

|

| M23 | ArCO – 5/4 Rest CO2: 5 Vol% ; O2: 4 Vol%; Ar: Rest |

|

| Process gas name | Multiple selection |

|

|---|---|---|

| M23 | ArHeOC – 4/3,1/2 Rest He: 4 Vol% , O2: 3,1 Vol%, CO2: 2 Vol%; Ar: Rest |

|

| M25 | ArCO – 13/4 Rest CO2: 13 Vol% ; O2: 4 Vol%; Ar: Rest |

|

| N1 | 100 N2: 100 Vol% |

|

| N2 | ArHeN – 20/2 Rest He: 20 Vol% N2: 2 Vol%; Ar: Rest |

|

| N2 | ArN – 2 Rest N2: 2 Vol%; Ar: Rest |

|

| N4 | ArNH – 2/1 Rest N2: 2 Vol%; H2: 1 Vol% Ar: Rest |

|

| N5 | NH – 5 Rest H2: 5 Vol%; N2: Rest |

|

| R1 | ArH – 2..15 Rest H2: 2 – 15 Vol%; Ar: Rest |

|

| R1 | ArHeH – 20/8 Rest He: 20 Vol%; H2: 8 Vol%; Ar: Rest |

|

| R1 | ArHeH – 40/10 Rest He: 40 Vol%; H2: 10 Vol%; Ar: Rest |

|

| Z | Ar + NO – 0,03 Rest NO: 0,03 Vol%; Ar: Rest |

|

| Z | ArC + NO – 2/0,03 Rest CO2: 2 Vol%; NO: 0,3 Vol%; Ar: Rest |

|

| Z | ArC + NO – 8/0,03 Rest CO2: 8 Vol%; NO: 0,3 Vol%; Ar: Rest |

|

| Z | ArC + NO – 18/0,03 Rest CO2: 18 Vol%; NO: 0,3 Vol%; Ar: Rest |

|

| Z | ArHe + NO – 30/0,03 Rest He: 30 Vol%; NO: 0,03; Ar: Rest |

|

| Z | ArHeC – 50/0,05 Rest He: 50 Vol% ; CO2: 0,05 Vol%; Ar: Rest |

|

| Z | ArHeHC – 30/2/0,05 Rest He: 30Vol% ; H2: 2Vol%; CO2: 0,05Vol%; Ar:Rest |

|

| Z | ArHeNC – 5/5/0,05 Rest He: 5Vol%; N2: 5Vol%; CO2: 0,05Vol%; Ar: Rest |

|

| Z | ArHeO – 15/0,03 Rest He: 15 Vol %; O2: 0,03 Vol%; Ar: Rest |

|

| Z | ArHeO – 30/0,03 Rest He: 30 Vol %; O2: 0,03; Ar: Rest |

|

| Z | ArHeO – 50/0,03 Rest He: 50 Vol %; O2: 0,03; Ar: Rest |

|

| Z | ArO – 0,03 Rest O2: 0,03 Vol%; Ar: Rest |

|

By submitting the data entered in the contact form by clicking on the button below, you declare that you have read the privacy policy and that you agree that the data provided will be collected and stored electronically.

The data is used only strictly earmarked for processing and answering your request.

By submitting the contact form you agree to the processing. You may revoke your consent at any time with future effect. In case of cancellation your data will be deleted immediately.